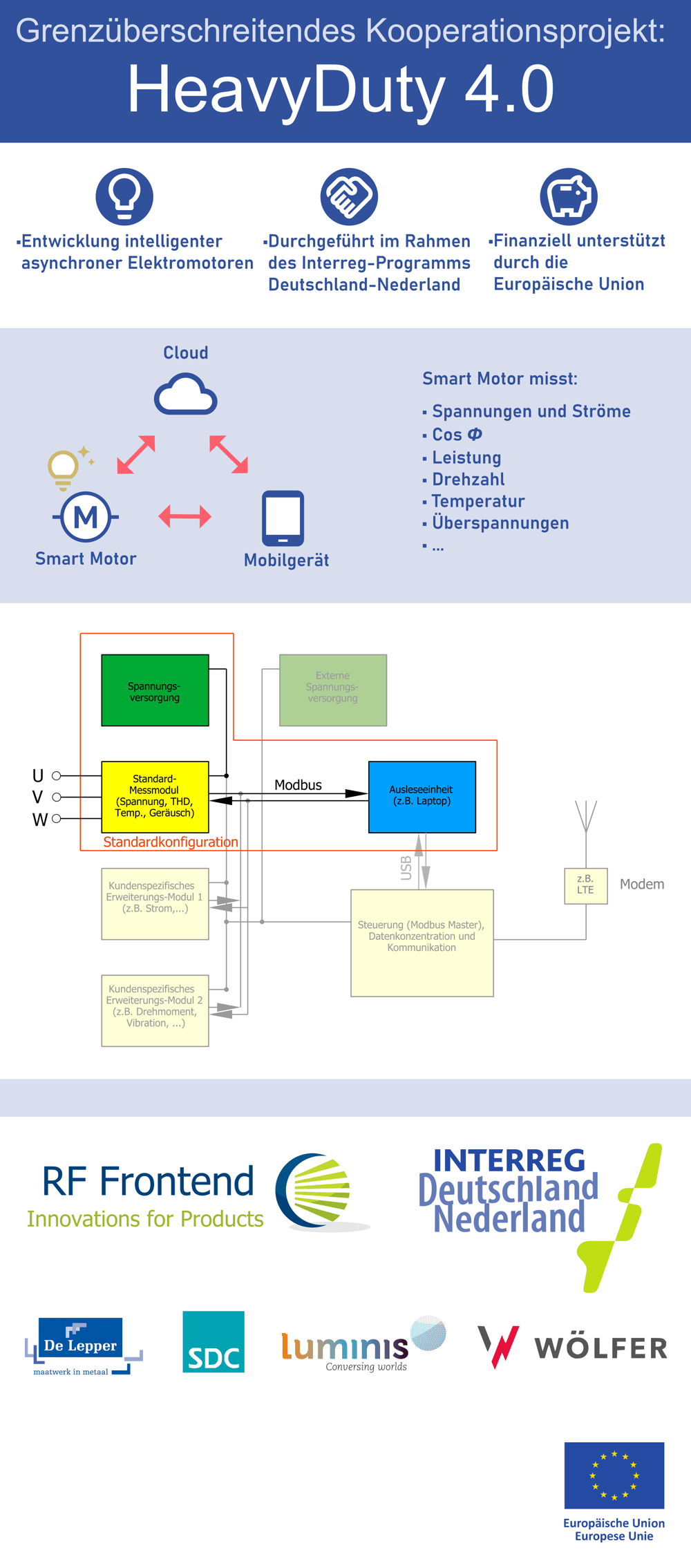

HeavyDuty 4.0

“Development of intelligent asynchronous electric motors for lifting tools with extremely high lifting capacities”

Funding code: Ref. 34-INTERREG V A-143080 Pr. no. 103211

Project sponsor: Euregio Rhine-Waal

Program: Interreg Germany Netherlands

Duration: 01.07.2018 – 30.10.2021

Funding RF Frontend: 564,504.41€ European Union

Summary

The asynchronous three-phase motor is by far the most widely built and used electric motor in the world. Approximately 65 to 70 percent of annual electric motor production is asynchronous three-phase motors. Motors are built up to a power class of 2 MW. Due to their inherent robustness, these motors form the backbone of the motorization of industrial plants. High availability of drive power is essential for the productivity of many plants. Such motors are often used in conjunction with frequency converters for speed regulation and precise control.

However, in practical use of these motors, e.g. as hoist motors for cranes in ports, various problems arise which affect both the availability of the motors and warranty aspects on the part of the manufacturer: shaft bearing wear, burnout, incorrect operation of speed and torque and electrical supply during voltage peaks.

A smart engine can detect and report impending problems. In this project, the engine was equipped with integrated sensors for most relevant parameters. These can be queried remotely via a network infrastructure, and various services can be developed based on them. The technology can also be used in other applications.

If you are interested in intelligent asynchronous motors, please contact Wölfer at https://www.woelfer-motors.com/de/kontakt or to the company RF Frontend regarding three-phase measurement technology.