Testing Solutions

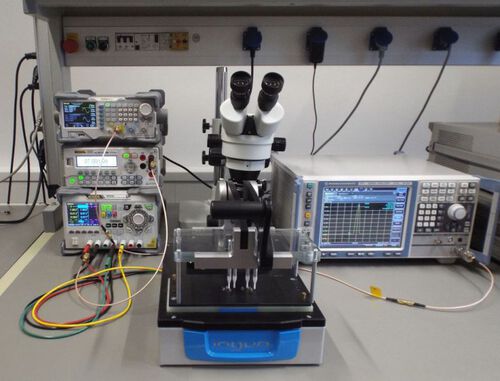

The test of the electronic assemblies under inspection is typically performed in a needle adapter. Here the required test signals are applied and the output signals of the circuit are measured and evaluated. If the DUT is also to be measured for its high-frequency characteristics, the test adapter must be designed accordingly. The required control electronics are integrated into the test adapter.

We use, among others, test tools from the company Ingun and set up the test adapters ourselves according to the requirements. We now have an extensive library for the control of typical test devices, so that new test tasks can be set up efficiently.

After the production tests of a production lot, the results are statistically evaluated so that mean values and standard deviations can be determined. This allows a production centering of the circuit design to optimize the yield.

We usually carry out the production tests ourselves, but we have also transferred high-frequency production tests to various production facilities on behalf of customers.

Auxiliary circuits are usually required to control the module to be measured. These are usually integrated into the test adapter. This drastically reduces the cable paths and enables a very compact design.